Optimizing Cannabis Post-Harvest Drying with Rack Configuration:

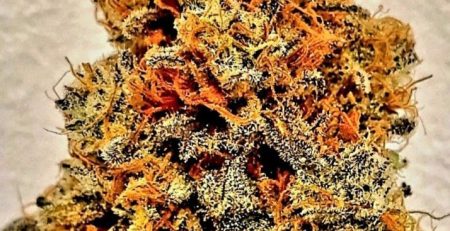

Cannabis cultivation is a meticulous process that culminates in the post-harvest phase, where proper drying & curing play a pivotal role in achieving premium quality end products.

One crucial element of this process is the configuration of drying racks, which directly influences the overall drying efficiency & quality of the final yield. In this post, we will explore key considerations & recommendations for optimizing cannabis post-harvest drying rack configurations.

1️⃣ Spacing & Air Circulation

▪️Adequate spacing between cannabis buds on drying racks is crucial to ensure uniform airflow.

▪️Optimal air circulation prevents mold, mildew, & uneven drying, ultimately preserving the potency & terpene profile of the cannabis.

2️⃣ Material Selection

▪️Choose racks made from materials with good ventilation properties, such as stainless steel or food-grade plastic.

▪️Avoid wooden racks, as they may absorb moisture & compromise the drying environment.

3️⃣ Adjustable Shelves

▪️Opt for drying racks with adjustable shelves to accommodate varying sizes of cannabis colas.

▪️This flexibility ensures an even drying process for different strains with diverse bud structures.

4️⃣ Temperature & Humidity Control

▪️Place drying racks in a controlled environment with consistent temperature & humidity levels.

▪️Implementing a drying room with proper ventilation & dehumidification systems enhances the precision of the drying process.

5️⃣ Darkness Preservation

▪️Protect cannabis from light degradation by utilizing opaque drying racks or positioning them in a dark room.

▪️Maintaining darkness during the drying phase safeguards the cannabinoid & terpene content of the buds.

6️⃣ Drying Time & Monitoring

▪️Monitor the drying time carefully to prevent over-drying or insufficient drying.

▪️Regularly check the moisture content of the buds using hygrometers to ensure the optimal moisture level is maintained.

7️⃣ Uniformity in Drying

▪️Rotate cannabis buds periodically on the drying racks to promote even drying.

▪️This minimizes the risk of mold formation & enhances the overall quality of the final product.

8️⃣ Quality Control

▪️Implement a stringent quality control process during the drying phase, inspecting for any signs of pests, diseases, or abnormalities.

▪️Remove any compromised buds promptly to prevent contamination & ensure a premium end product.

Achieving the best possible quality in cannabis post-harvest drying requires a thoughtful approach to rack configuration. By considering factors such as spacing, material selection, temperature control, & regular monitoring, cultivators can optimize their drying process & produce a final product that meets the highest standards.

In closing, adhering to these recommendations ensures not only the preservation of cannabinoids & terpenes but also the overall success of the cannabis cultivation journey.

What’s your preferred drying configuration?

Leave a Reply