Navigating the Pitfalls: Top 4 Flaws in Cannabis Cultivation Facilities

Navigating the Pitfalls: Top 4 Flaws in Cannabis Cultivation Facilities

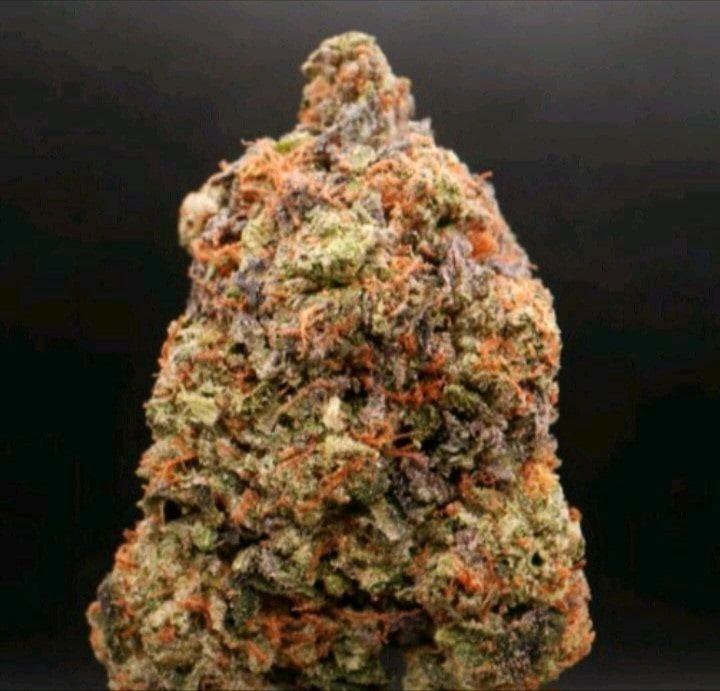

In the intricate world of cannabis cultivation, success hinges on meticulous engineering and design.

However, even the most well-intentioned efforts can encounter significant flaws. Let’s delve into the top four issues plaguing cannabis facilities today.

1️⃣ Lack of Inline Humidification in Engineering Design

The Flaw: Overlooking the importance of inline humidification in engineering design can lead to suboptimal growing conditions. Inconsistent humidity levels adversely impact plant health, affecting growth rates and resin production.

The Fix: Integrate inline humidification systems to maintain precise humidity levels throughout the cultivation space. This ensures a stable environment conducive to optimal cannabis growth.

2️⃣ HVAC Deficiencies: Undersized or Incorrect Choices for Colder Climates

The Flaw: HVAC systems that are either undersized or unsuitable for colder climates pose a significant challenge. Inadequate temperature control can stunt plant development and compromise yield.

The Fix: Tailor HVAC systems to the specific needs of the cultivation environment, ensuring proper sizing and compatibility with the regional climate. This guarantees a consistent and controlled atmosphere for cannabis cultivation.

3️⃣ Insufficient Dehumidification Capacities

The Flaw: Insufficient dehumidification capacities contribute to elevated humidity levels, exacerbated by oversized plants and additional moisture held by substrates. This can lead to various issues, including mold and fungal growth.

The Fix: Implement robust dehumidification systems tailored to the size of the cultivation space. This prevents excessive humidity, safeguarding plants against potential diseases and promoting a healthier growing environment.

4️⃣ Poor Light Distribution Set-ups and Excessive Light Energy Outputs

The Flaw: Inadequate light distribution and excessive energy outputs contribute to wasted resources and unnecessary strain on HVAC systems. This can compromise energy efficiency and strain overall facility infrastructure.

The Fix: Optimize light distribution setups to focus energy directly on plants, minimizing wastage. Additionally, carefully calculate lighting needs to avoid unnecessary energy consumption, reducing the burden on HVAC systems.

In an industry where success requires a delicate balance of science and practical application, addressing these common flaws is crucial for sustainable and prosperous cannabis cultivation.

As we navigate the complexities of facility design, let’s learn from past mistakes and continually refine our approaches to elevate the standards of cannabis cultivation practices.

Questions:

Do operators cheap-out on facility design due to capital budget constraints?

Or

Do facility management receive ill-advised information which they implement from consultants?

Leave a Reply